21st-Century Drafting

As watershapers, we can look at the rest of the architectural world and see that every other genre is benefiting more than we are from computers.

Bridge builders and skyscraper architects use computers to do everything from the simulated testing of three-dimensional structural models to the generation of detailed blueprints to be used on site. Even the designers of modest housing developments are now using computers to conduct 3-D virtual tours for prospective homebuyers and in specifying floor plans and structural details.

All of these marvels are being generated by computer-aided design (CAD) programs at a time when many in the watershaping business are still working with pens and pencils.

In skilled hands, drawings done with a compass and a T-square can be fantastic. For the rest of us, helpfully, CAD represents a way to generate quality plans that can be effective, evocative and communicative. And even those who can draw by hand may find that they can benefit from CAD’s flexibility and fast response time when it comes to customer requests.

FROM PAGE TO PRACTICE

Despite the growth CAD technology has seen in other architectural fields, it has yet to break through convincingly with watershapers. Without a doubt, some of the blame can be set at the feet of software vendors who haven’t adequately addressed the needs of watershape designers or demonstrated how existing technology can be effectively applied to watershape designs.

It’s also true that many potential CAD users have not even reached the stage where the applications questions are relevant, and are still struggling with fundamental questions about the available technology such as: What specifically should I buy? How long does it take to learn? How long before it pays off?

Those are all valid questions, and what I’ve found as I’ve worked to answer them for myself, my employers and my clients is that CAD systems afford the watershaper the freedom to define the extent of detail and uniformity required by the project. In other words, CAD is a highly flexible tool that enables you to determine how far you want to go in using its advantages.

|

Explorers and Conquerers In the early 1990s, industry-specific computer-aided design (CAD) systems presented themselves to the watershaping industry and met with some early excitement. But the aura of newness and fascination quickly gave way to concerns about costs involved with buying the software and the computer hardware needed to support a full CAD operation. The builders who had the inclination and the capital to support the purchase of CAD system did so and quickly sorted themselves into two distinct categories: those who explored the technology and those who conquered it. The first of these groups, the explorers, bought CAD systems and asked, “What can this technology do for me?” In many cases, companies with this approach spent considerable time sifting through the program features without a specific focus, often shifting uses from sales to project management and never really settling on a “purpose” in using the technology. This led to frustration – and many explorers turned away from computers in favor of tried-and-true, hand-drafted plans. In other cases, companies continued to use their CAD, but the technology had lost much of its early luster and the resulting work did not capitalize on the technology’s true capabilities. The second group, the conquerors, had a more specific vision: Whether the application was presentation for sales or accuracy in construction drawings, or both, the companies that successfully implemented CAD did so with a vision of the technology’s usefulness more firmly in mind. Their focus and direction eased their pathway to CAD efficiency. Both types of users usually became involved at some point in ongoing debates over whether the cost of CAD systems makes them worthwhile. Others have questioned and argued whether CAD enhances creativity and the designer’s ability to customize a project – or significantly limits it. The turning point of these debates lie not with the CAD system, but rather with individual designers and how they use what is, after all, only a tool. For the high-volume designer, there’s no doubt that CAD can become part of the assembly-line approach used by template tracers. By contrast, for the designer or firm looking to expand capabilities in custom work, the truth of the matter is that a CAD system can be used to generate watershapes with an infinite range of looks, styles, configurations, materials, elevations and details. What CAD enables you to do in truly custom designs is to change out elements very rapidly. You can, in effect, present a menu of ideas on “finished” or at least “well-polished” sets of plans for the client’s review and acceptance – and do so reasonably quickly. In other words, as a design tool, CAD is no more limiting nor any more liberating than a ruler or a T-square: It simply facilitates and enhances the objectives of those who explore its use – or conquer it. – C.W. |

Given that, I’ve had a tough time understanding why more companies haven’t gotten more involved in the technology. We at Florida Bonded Pools in Jack-sonville use CAD and have come to a simple realization: Understanding specifically what you want to do with a CAD system is the key to reaping the technology’s rewards.

In my case, I had the advantage of working with a variety of companies and setting up their CAD operations. I’ve seen how these programs work for everyone from high-end, custom builders to low-end, volume builders. The one thing they had in common was that they knew what they wanted to do with the technology.

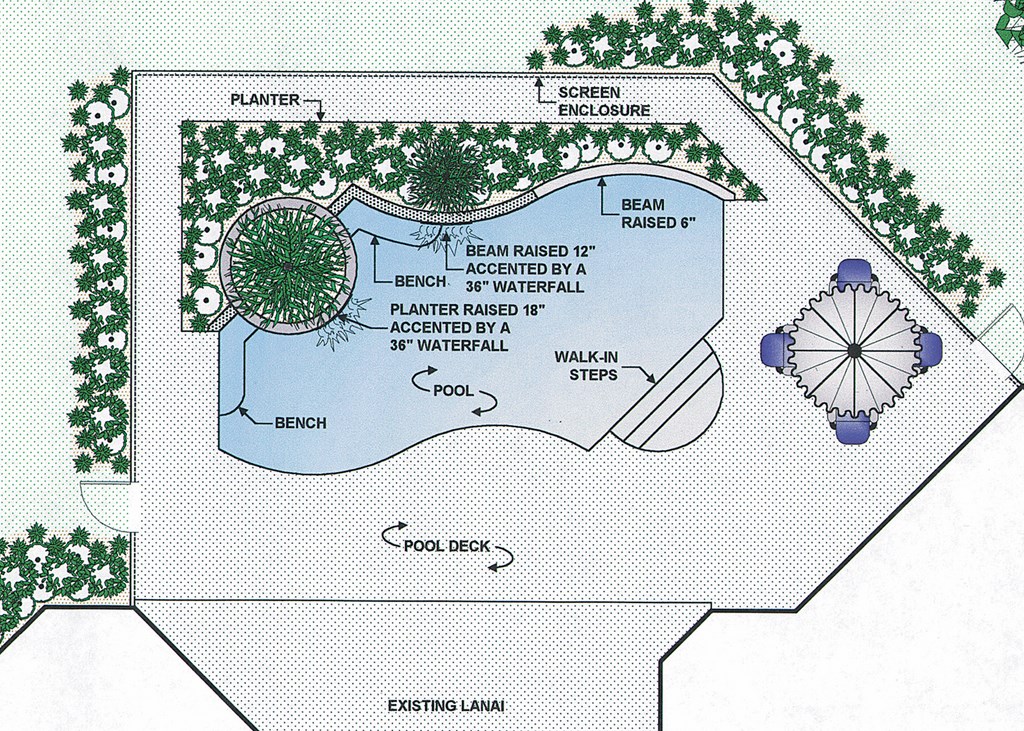

For volume builders, I found that crystal-clear CAD renderings gave the sales staff a way to stand apart from their competitors while offering a much wider array of pool shapes and features – so much so that they no longer had a template-tracing feel.

Other builders find that CAD helps them bridge the distinction between volume and custom work and reap benefits in two ways: More pools can be designed and bid more effectively, plus the quality of the design work picks up as well. The key here was and is the system’s ability to provide ample details quickly, which affords both the sales staff and the design and engineering departments the ability to respond rapidly to customer requests.

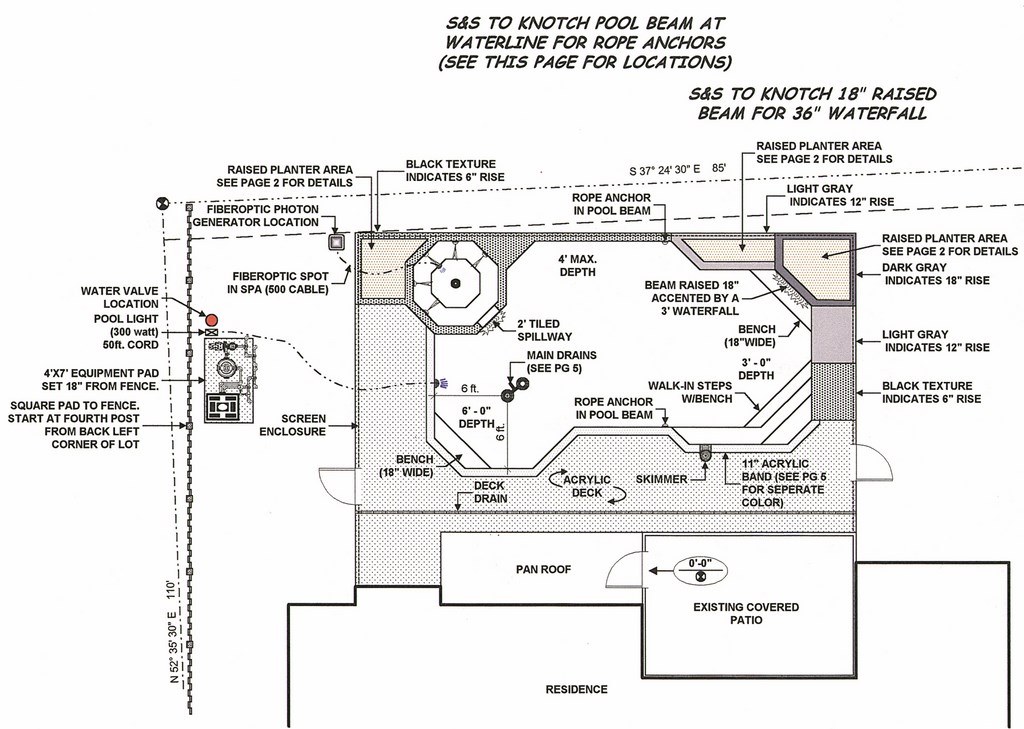

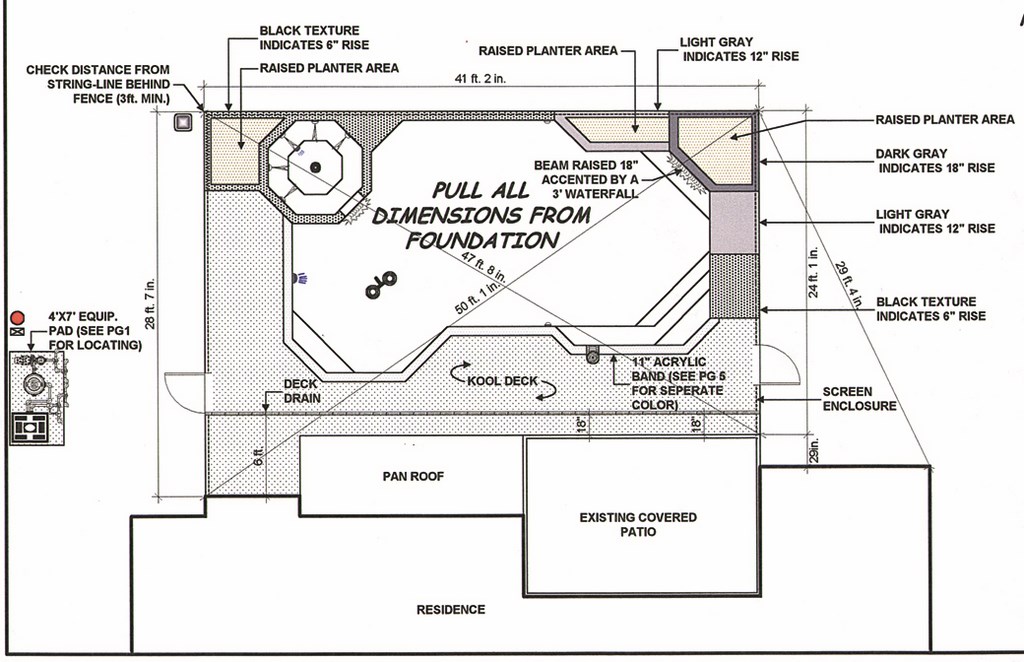

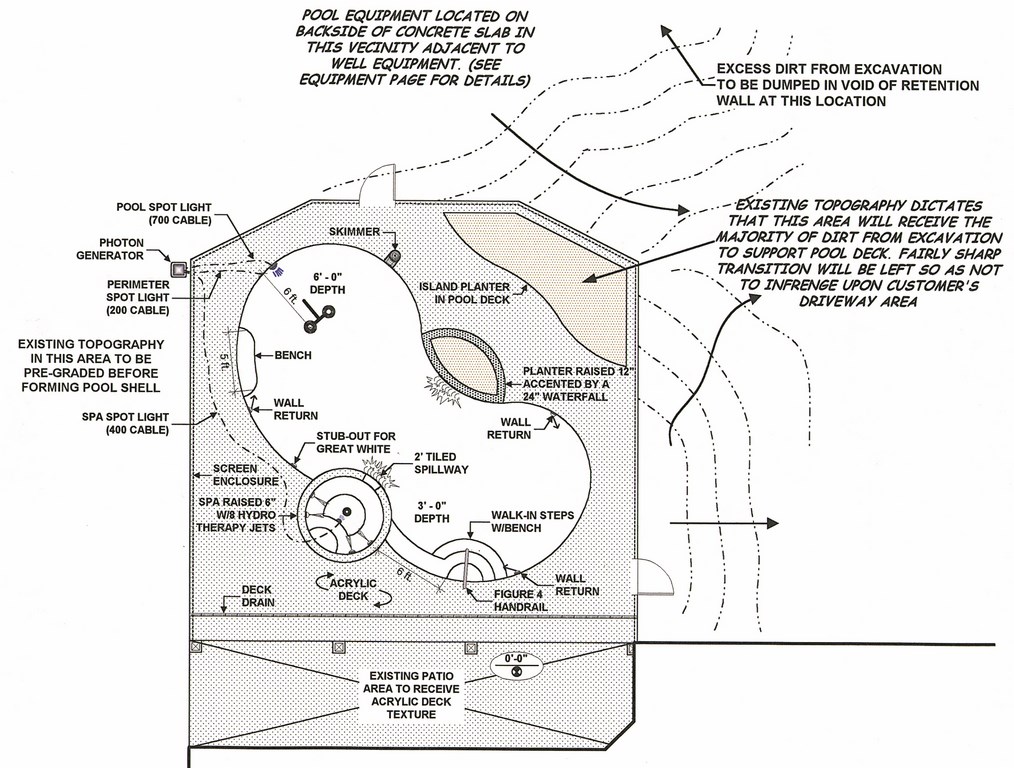

One of the companies I worked for, for example, was in transition to becoming a high-volume, custom builder. Our use of CAD technology was essential in maintaining the quality of our work while increasing the volume of production. In this case, providing ample detail for their construction department was vital, especially when translating conceptual drawings into finished products.

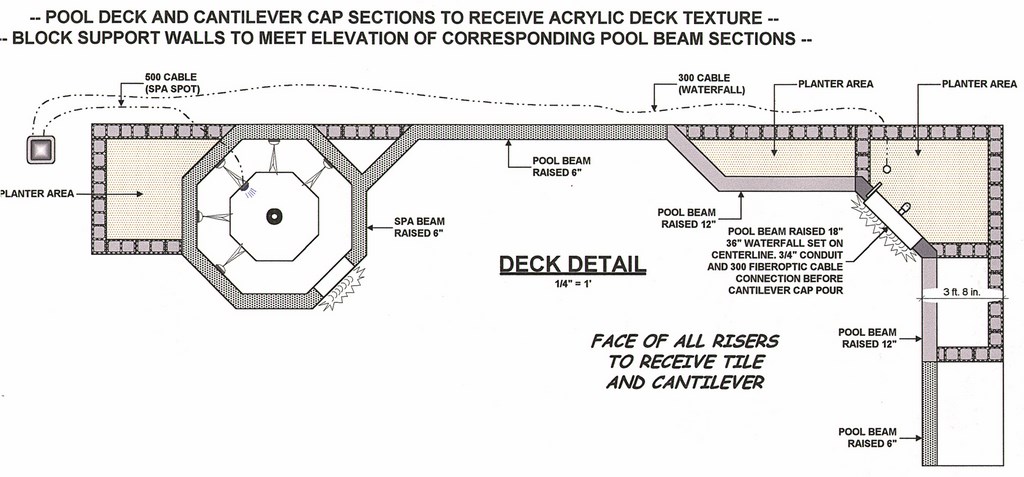

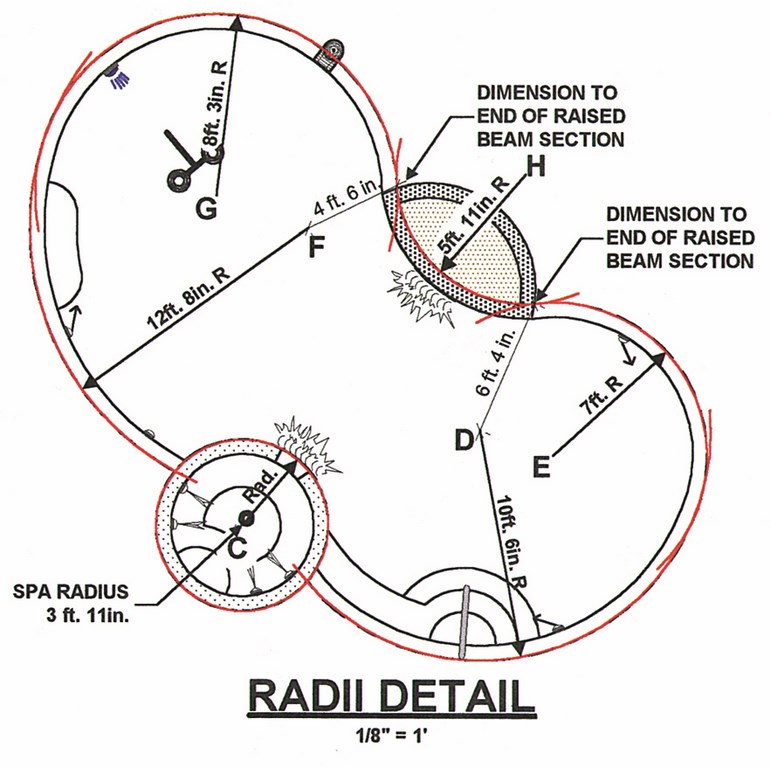

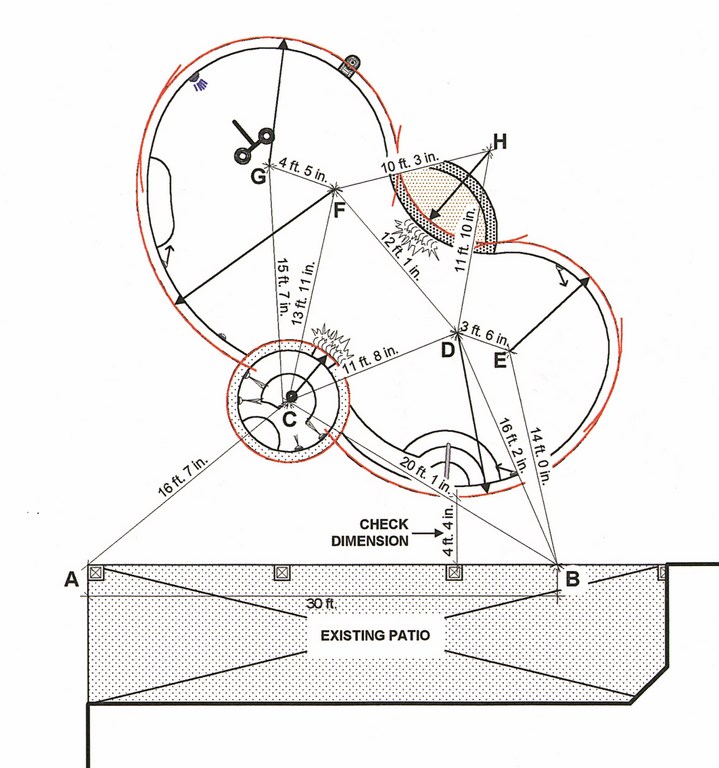

This flexibility is the heart and soul of CAD’s edge: It lets the designer work in layers of detail and with a variety of dimensional scales, line densities, textures and specific visual elements. It also lets the designer archive details as clip-art for everything from fire pits and trees to footpaths, rock fountains and shade structures.

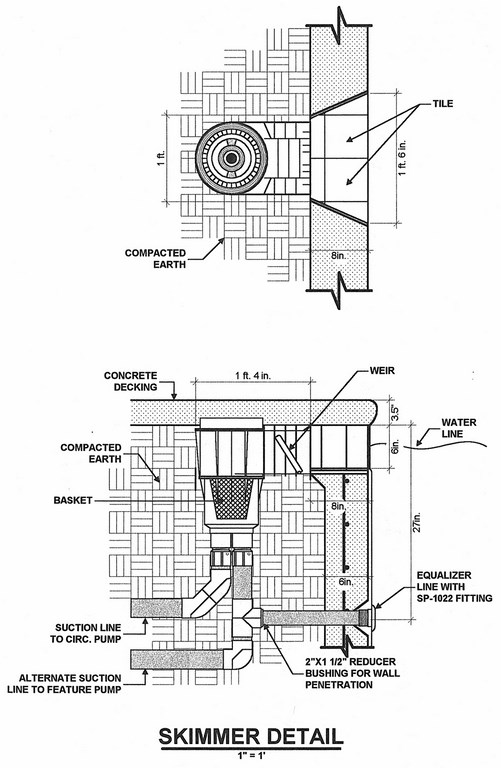

Later, on the construction side, you can take this store of information and turn it into detailed structural plans for use by excavators, plumbers and steel contractors. You also can establish precise elevation details and set locations for electrical outlets, plumbing and irrigation runs.

SOUNDS GOOD

This probably sounds like a sales pitch for CAD systems, but that’s true only in a limited sense. I’ve seen the effect these systems can have on site, in sales departments and with customers, and there’s a lot to be said for what their use can do by way of elevating a client’s perception of your professionalism as well as his or her expectations for the project.

A skilled operator truly can do amazing things with the technology, but CAD is like any other tool: When used by an unskilled operator or by one whose only aim is to generate designs very quickly, CAD drawings will lack detail and creativity. In this sense, CAD systems do not replace the need for thoughtful integration of design elements or attention to creative details. Rather, the systems simply enable you to create with a computer what a draftsperson does by hand – but with greater flexibility and, ultimately, greater speed and efficiency.

If you’re open to the potential these systems have for your business, now’s the time to go back and look at the key questions suggested above:

[ ] What should I buy? Like any tool, there are different CAD programs designed to suit different needs. If your design work includes integration with a wide variety of exterior elements and are not “just pools and spas,” you may want to look at systems intended for landscape designers, which offer a great deal of depth and detail for things like plantings and hardscape. If you focus on commercial fountains, a CAD program designed for architects may be the smart choice. And if you’re a mainstream pool builder, it’s likely that one of the industry-specific programs available to the trade will suit your needs.

One thing that almost all CAD programs have in common is that they are increasingly flexible. The ever-growing speed of computers and improvements in printer technology mean that newer programs can do more with less bother while allowing themselves to be tailored to specific needs.

[ ] What kind of learning curve is required? Make no mistake, if you’re from the hand-drawing school or do not have a great deal of experience using computers, adopting CAD will mean rethinking and relearning the way you do things. No matter your entry-level skill, however, most systems have on-board tutorial programs, and there are numerous CAD classes available from a variety of sources including program manufacturers and vendors, vocational schools and junior colleges.

In setting up a CAD-based design or sales office, you will need to invest both in the technology itself and in personnel who know how to use it. This doesn’t mean hiring directly from the computer science department of your local college or university. In fact, anyone with some drafting or design background can be up and running using CAD with just a week of training and practice. (True proficiency and skill, of course, take longer.)

[ ] How will it pay for itself? This is, of course, a critical question – and has two primary answers. First, CAD can help increase sales and thus pay for itself by improving the quality of your presentations and the flexibility of design options you offer to customers. Second, it can reduce construction costs through high levels of precision and detail in working drawings.

That second point is particularly significant: In a marketplace where errors can deal designers or builders costly, time-consuming body blows, a properly programmed CAD system can be of benefit in generating bullet-proof specifications. This increases the on-site accountability of crews and subcontractors and stands to lift the reputations of contractors working at all levels of the trade.

THE NEXT GENERATION

Technology is at the head of our societal vanguard these days, and watershapers have a good bit of catching up to do to reach the level of others in the architectural community.

And it’s not just a matter of being left in the dust within our own trade: In the year 2000, more Americans will turn 40 than ever before as the Baby Boom crests. Personal computers have been around for half the lifetime of these people: They represent the bulk of our pool of potential employees. They also represent the bulk of our potential clients.

Chris Walton is a designer for Florida Bonded Pools of Jacksonville, Fla. He’s been using CAD systems in his work for more than four years, for the most part on residential projects in the custom mid-range to high-end market but with occasional forays into commercial design. An accomplished CAD operator, Walton has also worked as an independent consultant assisting other watershapers in implementing their computer-aided design systems. Walton’s career began in the nuts-and-bolts end of the business: He has experience in steel installation, plumbing and concrete forming.