Standing Tall on Deck

It was one of those projects where aesthetics, technology, function and history all came together.

Installed on a pier on the waterfront in Hoboken, N.J., right across the river from the Manhattan skyline, the dry-deck fountain pictured on these pages was part of a civic development movement aimed at creating new public areas on both the New York and New Jersey shores.

Our company, Roman Fountains of Albuquerque, N.M., first became involved in the project in 1996, when we were contacted by the Princeton, N.J.-based project architect, Arnold Wilday Associates, Joint Venture. At that point, they were spearheading a joint venture still in its preliminary design phase.

The architects sought our expertise in defining the “nuts and bolts” of an elaborate fountain system they had in mind. They definitely knew what they wanted to see when they turned on the switch, they said, but they weren’t at all certain how to get there either mechanically or electrically speaking. We exchanged some basic design parameters by phone and fax and were on our way.

A PLACE ON THE RIVER

Civic projects at this level can take years to unfold. In this case, we were invited in October 1996 to attend a project-planning session that included the architect, the project team and officials from the Port Authorities of both New York and New Jersey. From the 72nd floor of the World Trade Center where the meeting was held, we could all see the long-neglected Hoboken waterfront and its Pier A. As I looked down on the site, I knew that a unique and ambitious renovation was beginning to take shape.

Perhaps best known as Frank Sinatra’s home town, Hoboken, with its red-brick waterfront buildings and the dark green wrought-iron structure of the Erie Lack-awanna train station, provided a backdrop for a dramatic combination of elements of the past along with the technology of the present.

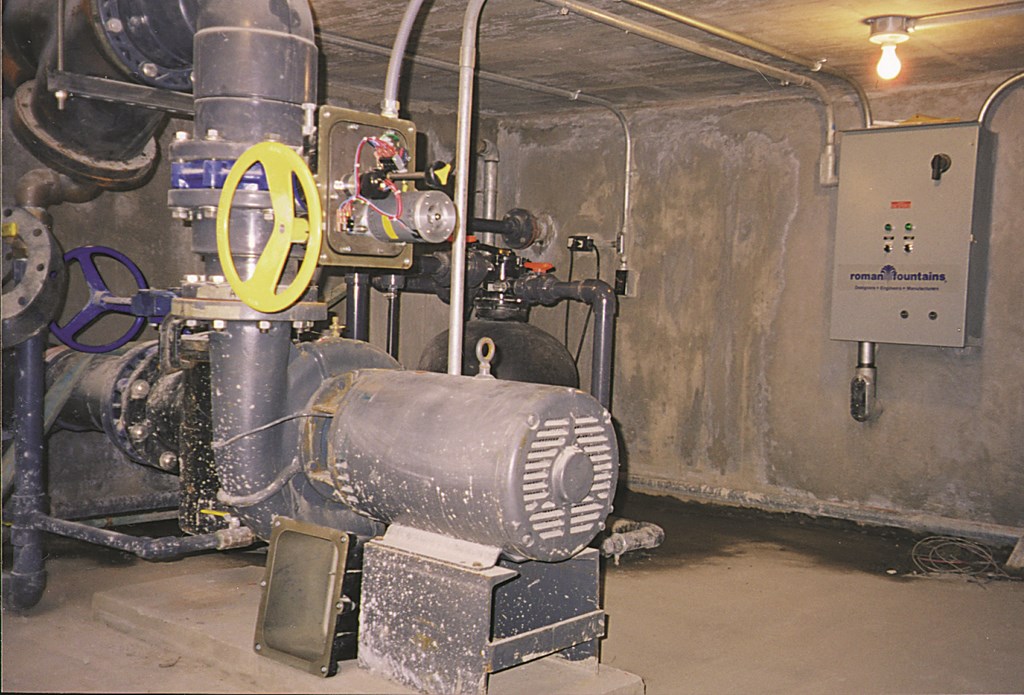

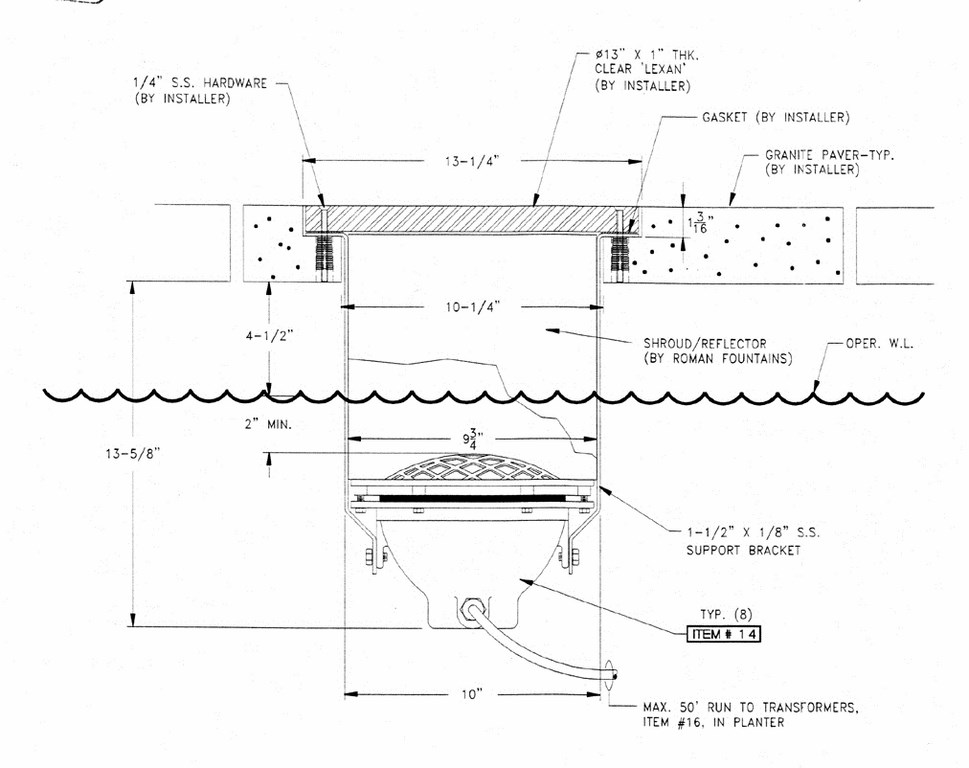

| LARGE-SCALE POWER: A 30-horsepower pump (top left) drives the display with a flow of 1,150 gpm with 68 feet of head at the nozzles; the water returns via 10-inch main suction and discharge pipes. The foam-aerator nozzles chosen for this dry-deck fountain (middle left) are swivel mounted and were chosen for their relative wind stability and high-level visual qualities (middle right). Granite pavers, 24 inches square and 3 inches thick, were core-drilled offsite to accommodate the nozzles (right). The pavers are supported on 8-inch-diameter, poured-in-place pylons seen at middle left. The lighting fixtures were wired through bronze submersible junction boxes (bottom left) and powered by three 1,000-watt transformers mounted in an adjacent planter bed. |

And it was a great and productive meeting: We all came out of it with a clear understanding of the project’s design criteria and the construction challenges and limitations we’d all face in carrying it off.

The big challenge was to build a vessel and fountain into an existing pier without compromising the integrity of its structure. Actually, the job would have been easy if we could have penetrated the pier and worked up from below; that was not to be permitted, however, so we had to take extra care in site evaluation and in choosing locations for equipment.

|

Into the Wind The design team determined the eventual 16-foot spray height for the dry-deck fountain featured in the accompanying story based on the footprint of the entire fountain in the context of its hardsacpe. As it turns out, 16 feet was the highest spray possible for viewing while still giving us control over the splash-zone, mist and wind-drift issues that confront most vertically inclined watershapes. In this case, a two-stage wind-control system was designed, specified and furnished for the fountain. The electronics in the wind-control system work in conjunction with an electrically actuated butterfly valve and an anemometer (that is, a wind-speed meter) located on an adjacent lighting standard. When the wind velocity reaches a pre-set, “first stage” velocity, an electrical signal is sent to the butterfly-valve actuator, opening the valve slightly. This diverts a portion of the flow back into the vessel and cuts the spray height in half. If the velocity hits a second setpoint, the display pump shuts down for a set time – or until the wind dies down – returning to operation at either full or half height depending on the prevailing wind speed. – J.M. |

At this stage, all we had been asked to do was to prepare schematics, construction specifications and preliminary cost estimates for a fountain system and its mechanical and electrical requirements. These documents were developed under the watchful eye of Roman Fountains’ senior design manager, Steve Shadle, and submitted to the architect and the New Jersey Port Authority for engineering review and for compliance with the site requirements and codes.

Once the schematics had been “massaged” by the various disciplines involved in the project, we took the review information, mark-ups and written comments and prepared a working set (still preliminary) of the installation drawings. These documents detailed all equipment, piping, conduit, wiring, utility requirements and offered complete, scaled blueprints and technical specifications — everything needed by contractors in preparing bids.

At this point, Roman Fountains joined the ranks of qualified bidders and submitted its price along with about six other suppliers.

FACING THE CHALLENGES

A year had passed since the initial October 1996 meeting before the public bidding process began. Kathy Wilson, our sales and marketing manager, followed the project as it slowly made its way through channels. Ultimately, J. Fletcher Creamer & Son of Hackensack, N.J., was selected as the general contractor for the pier portion of the overall project, including the fountain.

In turn, the general contractor hired us to supply the fountain’s specialized components and take care of system start-up. We signed on in this capacity in May 1998; production, delivery and equipment installation took place through the rest of the year and into Spring 1999.

But let’s back up a bit: The initial design criteria and parameters provided to us by the architect had included water volume and mass, spray type, spray height and a footprint for the fountain area. The objective: to provide a safe, durable and interactive fountain that could be enjoyed from a distance – or by getting wet.

We were also told that the design should complement the space as well as the pier environment. The architects wanted a waterfeature that would attract visitors to the newly designed park – but not one that would overwhelm the area or the many other amenities designed into it, including play areas for children, vending carts and an outdoor performance venue.

Another important criterion was safety, which was why the concept of a grade-level, dry-deck fountain, which eliminates artificial barriers and trip hazards at the fountain, had so much immediate appeal. Better yet for the pier, this sort of light, clean hardscape/pavement transition would allow light-vehicle traffic to traverse the deck to speed service and maintenance.

The most challenging aspect of the project was the fact that the fountain’s vessel had to be built into the old pier. Indeed, the Port Authority insisted that we maintain the integrity of the pier’s structure, which meant that the vessel would have to be deep enough to accommodate proper equipment installation but shallow enough to stay within a long list of pier-integrity requirements.

The vessel’s final dimensions spanned 24-by-24-feet at a depth of 2 feet with an operating water level of 18 inches. The nozzles we used made it possible to keep the depth to a minimum.

We also faced a challenge with the remote, poured-in-place pump room, lowering its height to the absolute minimum required to install the equipment with all proper clearances required by code. This meant that we needed to maintain tight tolerances for the pipe slope from the vessel’s floor to the pump room, and the contractor did a great job in getting it right on the first try. Improper pipe slope could have resulted in an air-trap condition that would’ve made it very difficult to maintain a functional flooded-pump condition.

SPECS ON DECK

Beyond the project’s many site, mechanical and hydraulic issues, the remaining major issue had to do with the manner in which the 24-inch-square by 3-inch-thick granite pavers – each weighing more than 200 pounds – were to be supported. We had a couple of options here, including custom-fabricated stainless-steel stanchions, extruded fiberglass structural skeletons and molded plastic leveling supports, each of which functions well on small systems.

|

A Cool Departure Over the past five years or so, dry-deck fountain systems have become more and more popular as both architectural features and public amenities – for lots of reasons. First of all, they’re safe. With a dry-deck design, you eliminate trip hazards and the body of water is completely enclosed. Second, the usual sorts of vandalism are foiled largely because the equipment is all hidden and inaccessible below grade. Third, they offer a streamlined, contemporary look that provides a nice departure from the traditional open-pool/ raised-curb fountain design. But the feature appreciated perhaps most of all by architects and municipalities and others who commission these fountains is the fact that deck-level systems basically disappear: They offer no problems when it comes to handicapped access (as mentioned in the accompanying text) nor any impediment to foot or light-vehicle traffic. (Photos courtesy Arthur Wilday Associates, Princeton, N.J.) J.M. |

In this case, however, we had heavier-duty requirements and decided to pour a series of reinforced-concrete pylons using 8-inch Sonotubes. Each pylon supports the corners of four pavers, each of which was shimmed using the “Pave-El” pedestal-support system made by Envirospec, Inc., of Buffalo, N.Y.

We set 3/8-inch gaps around each of the pavers, bearing two major factors in mind. First, Title 27 of the American with Disabilities Act dictates a maximum grate span of no more than l/2-inch wide. At the same time, the gap had to create enough open area to accommodate the 1,000 gallon per minute return flow to the vessel beneath the deck. There wasn’t much room for error in either direction!

As for the fountain and its plumbing, we prefabricated the 16 nozzle headers and associated plumbing at our facility in Albuquerque. We used 6-inch schedule 80 PVC pipe and fittings, and prefabrication was needed to control the locations of all nozzles to match holes core-drilled through the pavers while also accommodating all of the support pylons.

We also had to be sure that we had balanced water distribution for each of the nozzles. This was critical: We had eliminated the possibility of using individual nozzle-riser valves because of the tight height requirements.

| GETTING STARTED: The first run with just about any fountain system will dislodge construction and other debris that makes flow to the nozzles uneven (left). With a bit of fine-tuning, however, the fountain performs at peak height with all nozzles firing evenly (right). |

In other words, we just couldn’t afford any guesswork when it came to pipe layout or to take any installation shortcuts that can occur when you work without a well-conceived and detailed plumbing plan. At the factory, we were able to do a full-scale mock up of the header and nozzles to verify spray patterns as well as nozzle-to-nozzle balance issues. We also were able to establish and verify spray heights and anticipate splash patterns.

DEBUGGING DEBRIS

I don’t like to use the word “problems” in describing anything we do, but we did face the usual array of installation hassles that come with any large fountain system. In fact, we approach jobs like this one with what we in the company call the “fountain fact of life” in mind: Something invariably happens to knock you off stride.

In this case, there was a series of minor problems – all of them easily corrected. The suction sumps, for example, had become clogged with the usual construction debris, from soggy cardboard and leaves to chunks of concrete. We also found that a few pressure-test plugs had been left in the sump connections by the contractor; we removed them.

|

Right from the Start Straight through this project from its inception, the situation was just about ideal from our perspective at Roman Fountains. First, we had been involved from Day One and were able to see to all of the needs of a dry-deck system and the submersible lighting that came with it. Too often, fountain designers and manufacturers don’t get “invited to the party” until midway in the process or, worse, near the end – by which time certain fountain/hardscape issues are already “set in concrete.” Not the case here: We had full cooperation among all parties from start to finish – and we’re talking about lots of parties from lots of disciplines. Not only were we given a say in the initial and final project stages by supplying the system and handling the start-up: We also were asked to consult with the architect, the New Jersey Port Authority and the contractor during the installation phase. All in all, it was a project that was set up for cooperation and success from the start right on through to the dedication ceremony. – J.M. |

This was no big deal because of the way we handle start-ups, which involves running through a pretty extensive checklist. As we go, we usually discover (and can correct) these sorts of problems long before they cause any real trouble or system damage.

In one key check, for example, we sized up all the nozzles for true vertical orientation. As it turns out, a few of the nozzles had been knocked out of alignment during installation and required some routine adjustments.

For all our precautions, we found that later, when we fired up the display pump, some construction debris was still in the system and ended up clogging a few of the nozzles. A dual-strainer system installed on the display-pump system did catch a lot of debris, but some on the downstream side of the strainers (between the pump room and the pool) slipped through to create a few erratic spray heights.

We also encountered an unusual problem: Loose, fibrous material from bark used in nearby planters and tree wells was finding its way into the water. The strainer system was catching it, but it resulted in a need for frequent cleaning until the bark settled down into the planter beds.

All the bugs were out of the system by Dedication Day, and our clients are happy with the fact that the fountain has become a big attraction on Hoboken’s Pier. Architect Stephen Lederach said it all when he e-mailed us photos of the dedication: “The opening was superb,” he wrote. “The children had a ball playing around it, and we watched a jogger run through it to cool off. You made a dream a working reality!”

Jon Mitovich is president of Roman Fountains, a fountain-design and component manufacturing firm based in Albuquerque, N.M. He has been with the company since 1977, first as vice president and general manager, then as president. Well versed in all aspects of commercial fountain application, from design and development to contract management and corporate administration, he is a graduate of Southern Methodist University in Dallas and has completed classes in fountain design at both UCLA and the Harvard School of Design. Mitovich is also a member of the Construction Specifications Institute and the American Society of Landscape Architects.