Grand Solutions

It’s the nature of the game: One of the great sources of pride for any good watershaping business has to do with its ability to find solutions to difficult challenges – a new way to achieve something familiar when the established or conventional approach won’t work, for example, or dealing with site constraints that repeatedly send you back to the drawing board.

That’s the sort of pride we had coming out of our work on the Arthur J. Will Memorial Fountain and its accompanying splash pad at Grand Park in Los Angeles, and it was intensified by the fact that this was the restoration of a 60-year-old fountain that had originally been built with an entirely different approach from anything we’d consider today – but whose physical constraints we couldn’t escape on any level.

As we discussed in the first article in this two-part series (click here), the old fountain was built on a slab floated over a huge parking lot across the way from Los Angeles City Hall and an array of city and county court buildings. The parking lot was an immoveable, generally uncooperative obstacle to getting things done with any modern efficiency, but we had no choice and simply had to work with the not-so-great hand we’d been dealt.

MAKING READY

Last time, we defined the nature of the situation we faced with the two available penetrations through the roof slab of the garage that we had at our disposal. One of the shafts was part of the original fountain and included a steel water pipe we needed to remove – a feat we eventually achieved with a rig we borrowed from an oilfield-rigging company. But as we discovered, the shaft tapered as it descended toward the equipment room two floors down, so a tight space became even tighter.

To make this work, we inserted two eight-inch pipes all the way to the bottom of the shaft, where we could make pipe connections in the small space open to us within a large (and untouchable) support beam.

Originally, we had planned on using PVC, but with the adjusted velocities and pressures the plastic pipes would have burst, so we had to go with stainless steel. This left us to come up with custom manifolds for the two pipes that reached into the fountain bowl, which we realized we’d need to set at different levels to allow for all of the necessary connections.

| The process of working with the old fountain core was complicated by the fact that it tapered as it passed down to the equipment room. This led us to rethink our approach and redesign the manifold system, which we tested in plastic before having them fabricated in metal for connection to the descending lines, one of which ran straight down, while the other passed through a tangential hole in the core’s shaft. |

Once we tested a mockup of the manifold and checked it for its pressure and flow capacities, we sent drawings out to a fabrication shop to have two of them made in stainless steel.

While this was happening, the fountain bowl was being repaired and repointed to exacting specifications at the same time new concrete stairways and structures were being built on the fountain’s back side (that is, away from City Hall) to frame it at the park’s highest point. The general contractor took care of this portion of the flatwork and masonry using our plans for the fountain features that were to be added to the structures behind the fountain.

The gap between the garage roof and the fountain slab was greatest in the vicinity of the fountain – about six feet – giving us an irregular vault to work with in setting up our systems and working with a large, existing pipe that poked through the side of the main fountain shaft.

This between-slabs space was far from pleasant: We all dreaded the thought that we might get under there, peer into the darkness and find beady little eyes looking back at us from the darkness. By work rules, nobody could be down there for long, and that seemed to suit everyone just fine.

| With the manifolds in place, we made connections to the fountains rings and began to hear from neighboring high-rises that the bird’s-eye view of the resulting spaghetti was less than pleasing. So we doubled back and inserted concentric rings of removeable decking to hide the pipes and cables and made ready to test the systems and prepare the fountain for its debut. |

Once everything emerged into the bowl through the shaft, it was largely a matter of organizing nozzles, jets and lights to the design specifications set up by Fluidity Design Consultants (Los Angeles) and the manufacturer of the fountain components, Crystal Fountains (Toronto, Ontario, Canada).

Somewhere along the line, however, one of the stakeholders mentioned that the fountain mechanicals were plainly (and distractingly) visible from the high-rise buildings around the park. This sent us back to the drawing board once again to devise a set of concentric tile rings we supported on a frame structure we had to work in and around the typical fountain-works spaghetti.

A prime consideration in setting up these rings was long-term serviceability: We knew the fountain would need routine service given the extremely hard water found in Los Angeles; we also knew that the flexible piping would eventually need replacing. As a result, we set up the tile rings for easy removal as necessary.

TIGHT TOLERANCES

Over on the splash pad, we encountered an entirely different set of challenges – and some massive headaches.

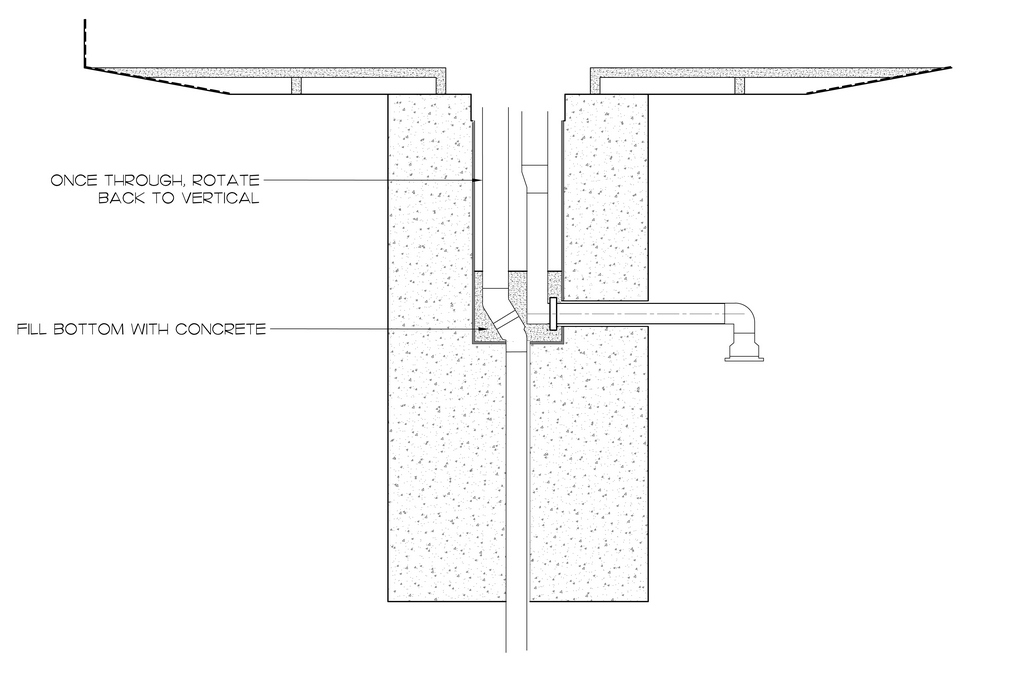

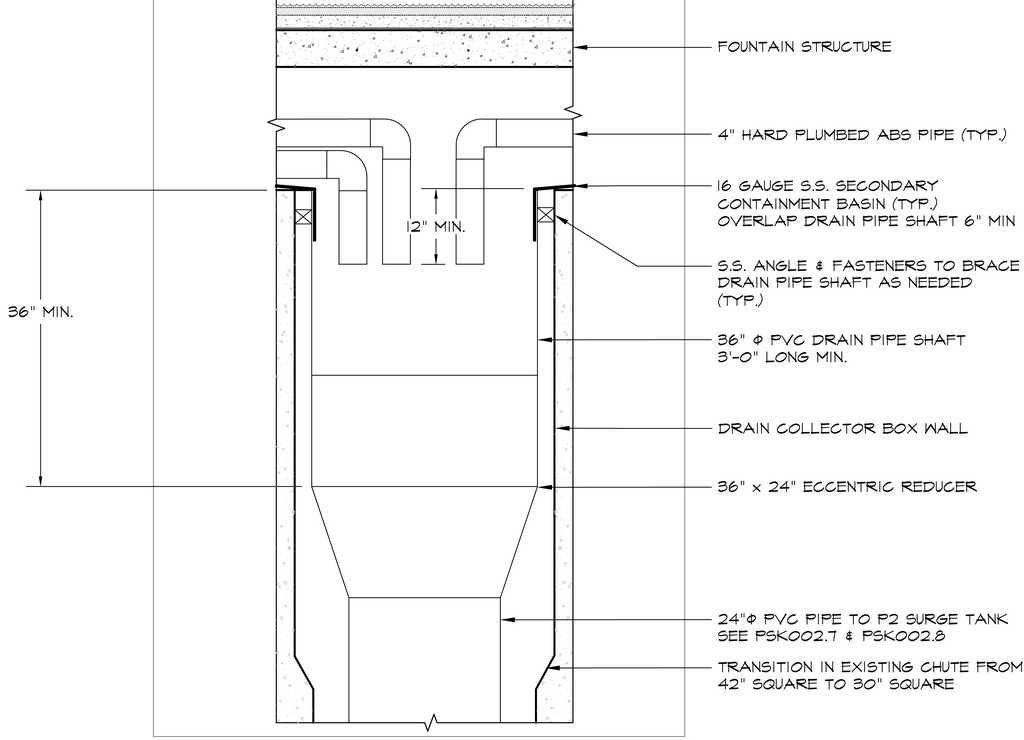

First, when we explored the ventilation shaft we’d be repurposing to drain the deck down to a surge tank two floor below grade, we found that it, too, tapered as it descended and had been lined with a tar-like material that, given our experience with the lead wool, we simply didn’t trust or want to touch in any way. So we decided to bypass any such concerns by setting up a large-diameter pipe we could run to the bottom of the shaft with a funneling top that we could effectively seal.

| The splash pad’s plumbing offered its own set of challenges, many of them related to the fact that we had just one existing penetration to accommodate all 23 of the system’s large drain pipes. Once again, we had to work with an oddly shaped shaft and began to see when all of the lines converged at the shaft just how complex the puzzle had become. |

Second, the drain lines were all gravity-driven, so we couldn’t stack any pipes without creating backflow issues. In all, there were 23 four-inch lines we had to fit into the shaft to pass through a circular hole in a plate we fabricated atop the funnel. To say making this work was a model of pipefitting excellence would be putting it mildly: A lot can happen between dry-fitting and actually gluing up such an intricate pipe array.

A third and final complication had to do with the decking: It’s a beautifully patterned granite composition defined by the developer who was funding the park. The material he wanted was quite specific with respect to the number of large spots that could appear in any square foot of granite, which was fine by everyone given adequate communication with the supplier.

But the material had been sourced in China and had been ordered to arrive on site as precut, pre-fit pieces, ready for installation. Making that sort of jigsaw puzzle work is hugely challenging even across a small area – and this was a distinctly large space at 120 feet across. Furthermore, the design called for the surface to be dead flat and level to within a sixteenth of an inch – again, a special challenge with precut, pre-fitted material.

| Once inside the drainage vault, the 23 lines all had to function by gravity and converge in a relatively small circle we established to carry the flow down to the equipment room. Needless to say, we did a lot of dry fitting before we began to do any gluing and had to achieve accuracy at a level uncommon to the average piping project. We also had our work cut out for us on the interactive fountain’s surface, carefully assembling pre-cut pieces to form a seamless, intricately patterned deck. |

With great care taken in preparing the substrate and precise placement of pipes and jet penetrations across the entire surface, this all came together remarkably well – and beautifully.

But there was one more thing: The covers for the lights were large enough (at six inches in diameter) that they presented something of a slip hazard, especially to the smaller feet of children playing on the splash pad. The idea of sandblasting the lenses to roughen their surfaces was proposed, but the lighting team feared it would have a diffusing effect on the LEDs, so we all stepped back and came at it again.

This time, the idea was to pattern the sandblasting across the lens surfaces in such a way that the lighting intensity wasn’t compromised or the beam pattern too greatly diffused. Once some test lights came back with favorable slip-resistance factors, the last of the many challenges posed by this project had been resolved to everyone’s satisfaction.

GOOD TO GO

Rounding things out, once we’d placed all the pipes up on the fountain deck and run them through the existing penetrations into the mechanical rooms – placed one pretty much on top of the other on the second and third floors below grade in the heart of the parking structure – we had in the case of the splash pad to figure out how to get the lines where they needed to go within the parking structure.

As noted previously, we couldn’t make any core cuts through the beams, and the ceiling areas were already occupied by a network of sprinkler lines and conduits of various types and dimensions. For all that, we had to make everything fit in above the six-foot, eight-inch vehicle-height limit – perhaps as difficult a set of tasks as any we faced on site.

| Day and night, the restored and artfully expanded Arthur J. Will Memorial Fountain is a marvel: a multi-purpose playground for children, a performance space for Grand Park events and in all ways a beautiful anchor — opposite the iconic Los Angeles City Hall – for the park’s west end. |

Then there was, at long last, the opening ceremony. The mayor’s office asked us to rig up a ship’s wheel near the fountain that the mayor was to spin to “activate” the new fountain. That posed no operational problems, but its theatricality was actually tough to manage, as there was no cellular link that could penetrate from the fountain deck to the mechanical rooms.

|

Drought Dodging By the time the fountain discussed in the accompanying text was initiated in 2012, Los Angeles was in the throes of a period of severe drought – a time when lots of fountains and waterfeatures around the region were being deactivated to save water and make municipalities appear to be direct participants in conservation efforts. Soon after the Grand Park waterfeatures came on line, they were caught up in the expected controversy. Helpfully (and wishfully), the city commissioned a study that ultimately showed that the Arthur J. Will Memorial Fountain and its accompanying splash pad were water wise beyond expectations because of the nature of the flows and the way water was captured within the system. It was quite a relief that the fountain was allowed to continue in operation and has since become a fixture of the city’s core landscape. Continued operation was indeed a fortunate outcome, because the greatest threat to fountain systems is the damage that comes when they are idled for any considerable period of time. In this case, we dodged the issue and all is well. — J.W.Z & C.R. |

To make it work, we placed big-voiced members of our staff at key positions to relay commands from the fountain deck down a couple flights of stairs to the control rooms. Happily for everyone involved, the flagging system worked, the fountains started up with little delay and the dedication ceremonies came off without a hitch.

Through the years, we’ve been involved in many complex projects – and as we noted at the outset of the first article in this two-part series, historical restorations tend to offer more than their fair share of potential (and actual) headaches.

For all that, we at Outside the Lines (Anaheim, Calif.) love tackling these restorations, especially when there are upgrades involved that will take the revised fountain to new and better levels of performance. In this case, for example, while the core of the fountain array for the remodeled Arthur J. Will Memorial Fountain is similar in profile to the original, the design team took full advantage of advances in fountain technology that had emerged in the more than 60 years since the fountain was first dedicated in 1958.

It’s here that we can identify our greatest source of pride: Working with old systems and, as in the case of the Grand Park fountain, old constraints can make for rough patches and long days. But with skill, persistence and the support of an exemplary project team, we persevered, figured things out and kept moving forward even when the project was shut down for weeks to allow for a lead abatement protocol to be completed.

Hands down, these are great projects, even fun – and for us, Grand Park stands among the most memorable, satisfying and enjoyable of them all.

J. Wickham Zimmerman is Chief Executive Officer of Outside the Lines, Inc., a design/build construction company that specializes in creating one-of-a-kind rockwork, waterfeatures and themed environments for retail entertainment, hospitality, gaming and golfing projects around the globe. Contact him at [email protected].Chris Roy isDirector of Creative Design at Outside the Lines. Contact him at [email protected].